What is the difference between low, medium and high pressure watermist fire suppression?

Low pressure

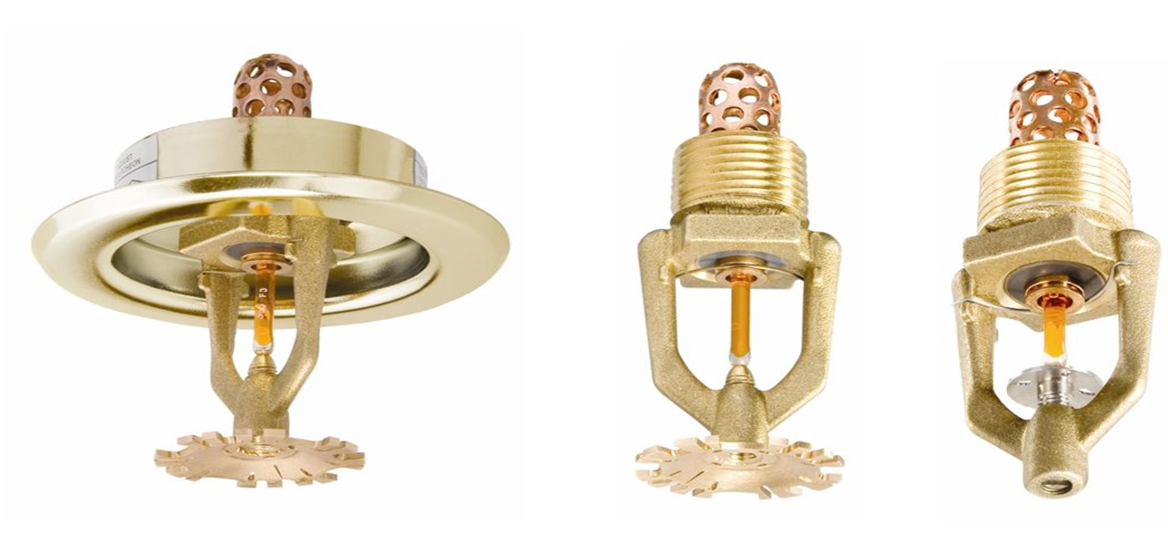

Low pressure visually resembles traditional fire sprinklers and may operate at similar pressures but utilise slightly different principles to generate small droplets of water mist. This means that while components may resemble a sprinkler head, the primary method of suppression is displacing the oxygen and cooling of the fire.

A range of open and automatic ‘heat sensitive’ low-pressure water mist nozzles is illustrated above. These have operating pressures of between 4.0 and 12.0 bar.

Low-pressure open nozzle systems are typically used for the protection of hazards involving flammable liquids such as gas turbines. The addition of specified surfactants (such as aqueous film-forming foam (AFFF) into system pipework will maximise extinguishing performance against these types of fires throughout the protected space. These nozzles are also suited for the protection of rooms, corridors and spaces where light-to-moderate fire loads of ordinary combustibles exist.

Medium pressure

These systems have been primarily used for local applications as low-cost alternatives to high-pressure systems. With a maximum operating pressure of 35 bar, they have been mainly used for the protection of diesel engine generator sets, boiler firing platforms and lube oil systems etc.

High pressure

High-pressure systems reduce oxygen concentration at the flame front in both object protection and total flooding applications. They can be particularly effective in completely or partially enclosed spaces, particularly where the fire is large in relation to the space.

Read more - What are the different types of watermist nozzles for fire protection?